The Role of AR and VR in Warehouse Management

Introduction

Warehouse management plays a key role in ensuring that products are stored, handled, and delivered smoothly. Recently, technologies like Augmented Reality (AR) and Virtual Reality (VR) have started to make an impact. These technologies are helping warehouses improve productivity, reduce mistakes, and make work safer for employees. In this article, we’ll explore how AR and VR are changing the way warehouses operate.

What are AR and VR?

Augmented Reality (AR)

Augmented Reality (AR)

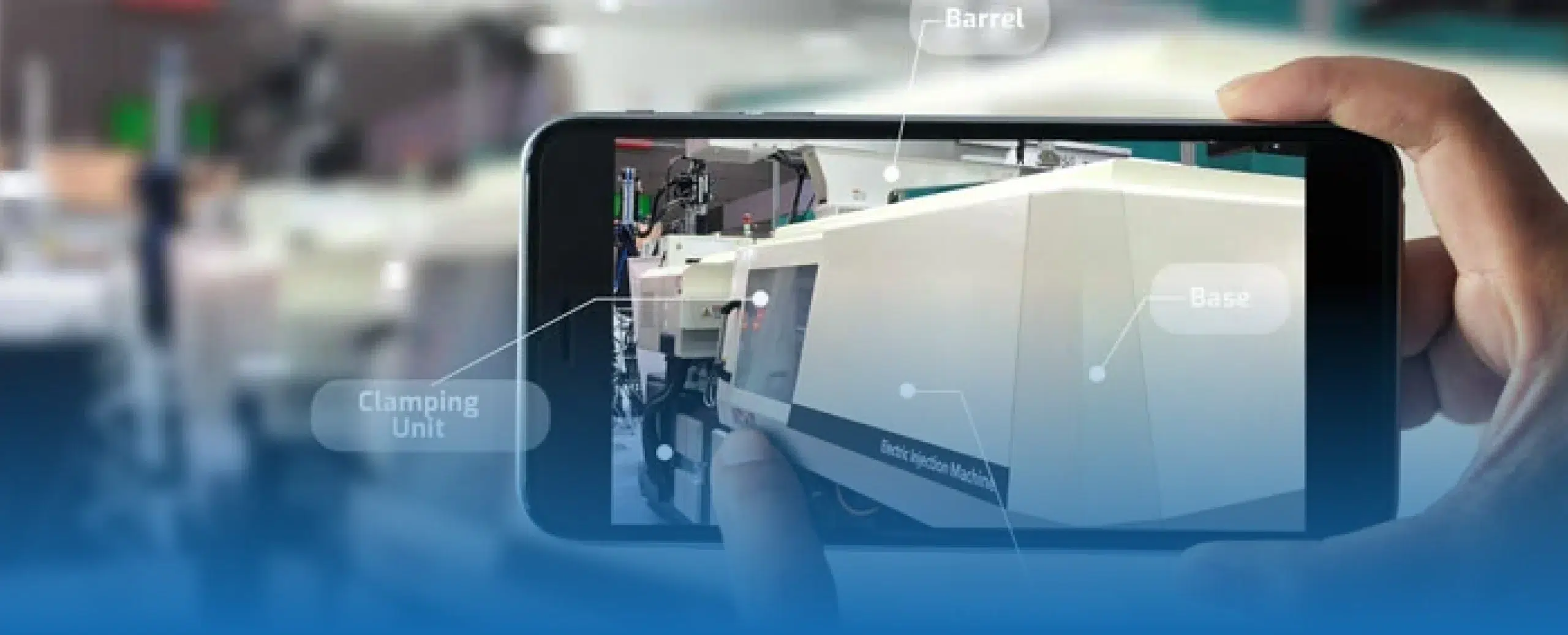

AR, or Augmented Reality, adds digital information to the real world around us. Imagine looking at a shelf through special AR glasses or a tablet, and seeing arrows or text on the screen pointing you to the exact product you need to pick. This digital overlay helps workers by showing them instructions directly in their real environment, saving time and reducing mistakes.

Virtual Reality (VR)

Virtual Reality (VR)

VR, or Virtual Reality, creates an entirely digital world that feels like a real place. Workers wear VR headsets that block out the real world and place them in a virtual warehouse or other simulated environment. In this virtual space, they can practice tasks, such as driving a forklift or organizing products, without actually being in a physical warehouse. This allows workers to safely learn and train in a realistic setting, helping them get better at their jobs before they perform tasks in the real warehouse.

How AR and VR Help in Warehouse Management

Real-World Examples of AR and VR in Warehouses

Several companies are already using AR (Augmented Reality) and VR (Virtual Reality) to improve how their warehouses operate, making them faster, safer, and more efficient. Here are some examples of how these technologies are being used:

DHL

DHL

DHL, a global logistics company, uses AR glasses to help warehouse workers find products more quickly. These smart glasses display helpful information directly in the worker’s line of sight. For example, the glasses can show the fastest path to an item on a shelf, saving time and effort. This makes the process of picking orders quicker and more accurate, leading to faster deliveries to customers. Workers don’t have to waste time searching for items or figuring out where to go next because the AR glasses guide them along the way.

Walmart

Walmart

Walmart has started using VR to train its employees, especially in areas like customer service and stocking products on shelves. In the VR training program, new employees can practice various tasks in a safe, virtual environment. For example, they can learn how to organize products, help customers, or navigate a busy store without actually being in the real store. This kind of training allows Walmart to teach workers important skills before they interact with real products and customers. It saves time and resources because employees can practice virtually without tying up space or inventory in the physical store.

By using AR and VR, these companies are improving warehouse operations, making training more effective, and helping workers perform tasks more quickly and accurately. This technology is becoming an essential tool in modern warehouse management.

Challenges and Limitations

Although AR (Augmented Reality) and VR (Virtual Reality) offer many benefits to warehouse operations, there are also some challenges that companies need to consider before adopting these technologies.

Future of AR and VR in Warehouse Management

As AR (Augmented Reality) and VR (Virtual Reality) technologies keep improving, we can expect to see even better features that will make warehouse operations more efficient and safer.

Lighter and Cheaper AR Glasses

Lighter and Cheaper AR Glasses

In the future, AR glasses may become lighter, smaller, and less expensive. Right now, the glasses can be bulky and costly, which makes them harder for smaller warehouses to afford. However, as technology advances, these glasses will likely become more affordable and comfortable to wear. This will allow more warehouses to adopt AR technology and use it to help workers find products faster, improving efficiency across the industry.

More Realistic VR Training

More Realistic VR Training

VR training programs will likely get even more realistic. Right now, workers can use VR to practice tasks like stocking shelves or operating equipment in a virtual world. As VR technology gets better, these training experiences will feel more lifelike. Workers may be able to practice even more complex tasks, such as dealing with emergencies or handling different types of machinery. This will help them prepare for real-world situations without any risk, improving their skills before they step into the warehouse.

Greater Integration and Automation

Greater Integration and Automation

The future may also bring better integration of AR and VR with other systems, like warehouse management software. This could allow AR glasses to pull information directly from the warehouse database, showing workers real-time data about inventory, shipment statuses, or product details. VR could be used to simulate entire warehouse environments, allowing managers to test different layouts and operational strategies in a virtual setting before making changes in the real world.

These advances will make warehouses even more efficient, safer, and easier to manage. As AR and VR continue to develop, we can expect them to become essential tools for warehouse operations, helping workers do their jobs better and faster.

Conclusion

AR and VR are changing how warehouses work by making them faster, safer, and more efficient. These technologies help workers do their jobs better, improve training, reduce mistakes, and keep everyone safer. While there may be some costs and challenges at first, the advantages of using AR and VR make them a smart choice for companies that want to stay ahead of the competition. As these technologies keep getting better, they will become even more important in warehouses, leading to smarter and more efficient operations.

Related Post

-

F

-

A

-

Q

AR (Augmented Reality) and VR (Virtual Reality) are technologies used in warehouses to improve efficiency, training, safety, and reduce errors. AR helps workers by showing information in real-time, while VR allows them to practice tasks in a virtual environment.

Yes, both technologies can improve safety. VR can be used to simulate emergency situations for training purposes, while AR can alert workers to hazards in real-time, helping them avoid accidents.

AR can give workers real-time guidance, such as visual instructions, to help them pick the right products and avoid mistakes. VR training allows workers to practice tasks before they do them in real life, reducing errors.

As the technology improves, AR glasses will become lighter and more affordable, and VR training programs will become more realistic. This will make it easier for companies to adopt AR and VR, leading to even smarter and more efficient warehouse operations.

While AR and VR can be beneficial for most warehouses, they are especially useful for larger warehouses with complex tasks. Smaller warehouses may need to carefully consider the investment before implementing these technologies.

The key benefits include faster operations, safer working conditions, better training for employees, fewer errors, and more efficient warehouse layouts. These improvements lead to higher productivity and better customer satisfaction.

Want to Scale

Your Business? Let’s Meet & Discuss!

CANADA

30 Eglinton Ave W Mississauga, Ontario L5R 3E7

INDIA

3rd floor Purusharth Plaza, Amin Marg, Rajkot, Gujarat. 360002

Get a Quote Now

Let's delve into a thorough understanding of your challenges and explore potential solutions together

Augmented Reality (AR)

Augmented Reality (AR)