Augmented Reality for Supply Chain Visibility – Real-Time Insights and Problem Solving

Introduction

What is Augmented Reality (AR)?

What is Augmented Reality (AR)?

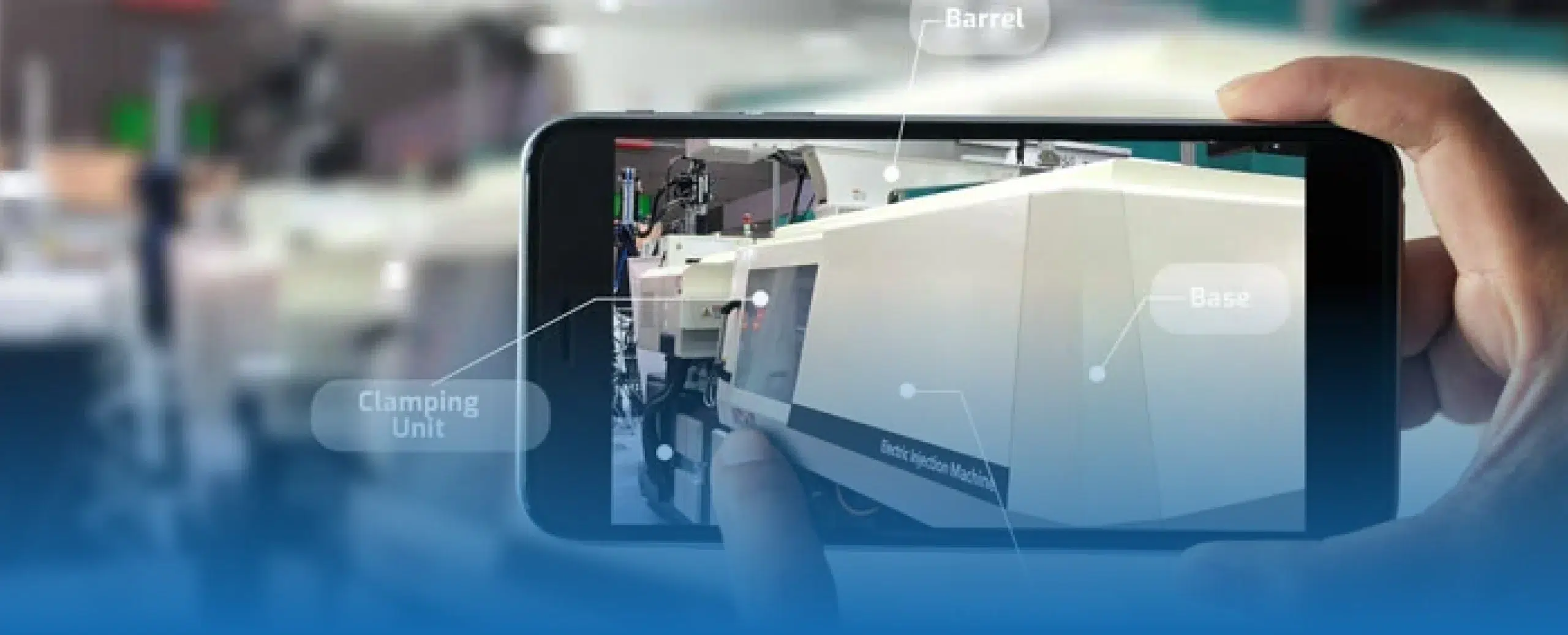

Augmented Reality (AR) is a technology that overlays digital information (like text, images, or animations) onto the real world. Using devices such as smartphones, tablets, or AR glasses, users can see digital data as if it’s part of their actual surroundings.

Importance of Real-Time Insights in the Supply Chain

Importance of Real-Time Insights in the Supply Chain

In the supply chain, real-time insights allow businesses to see what’s happening right now in warehouses, shipping routes, and inventory levels. This visibility helps companies respond quickly to issues and optimize their operations.

This article explores how AR can improve supply chain visibility, offer real-time insights, and help solve problems faster.

Understanding Supply Chain Visibility

What is Supply Chain Visibility?

What is Supply Chain Visibility?

Supply chain visibility is the ability for companies to see and track products as they move through each step of the supply chain – from the supplier, through warehouses and transportation, and finally to the customer. This involves real-time access to important data, like where items are located, their expected delivery time, and any issues that could cause delays.

Having strong supply chain visibility is essential because it means companies can understand what’s happening at every stage of the product journey. With this information, they can act quickly if problems arise, like a delay in shipping or a shortage in inventory. By keeping an eye on the whole process, companies can make better, smarter decisions that improve their overall operations.

Benefits of Improved Visibility

Benefits of Improved Visibility

When companies have clear visibility in their supply chain, several positive things happen:

Fewer Errors

Fewer Errors

With real-time tracking, companies can quickly detect and correct mistakes, such as misplaced items or incorrect shipments. This reduces the risk of sending the wrong product to customers or facing delays.

Improved Delivery Times

Improved Delivery Times

With better visibility, companies can plan and manage delivery schedules more accurately. They can avoid delays by adjusting quickly if there are unexpected issues, like a problem with transportation or a stock shortage.

Cost Savings

Cost Savings

When companies can track products accurately, they can avoid unnecessary expenses. For example, they can reduce extra shipping costs from fixing late or incorrect deliveries. Visibility also helps them manage stock more effectively, so they don’t over-order or run out of products.

Increased Reliability

Increased Reliability

When companies know where products are and when they’ll arrive, they can keep promises to their customers. This makes the entire supply chain more dependable. Customers are happier because they get their orders on time, and the company builds a better reputation for reliability.

How Augmented Reality Improves Supply Chain Visibility

Augmented Reality (AR) is a tool that shows digital information in the real world, helping workers in the supply chain get clear, instant insights. Here’s how it can make supply chain processes smoother and faster:

Key Applications of AR in Supply Chain Management

Augmented Reality (AR) helps make supply chain tasks faster, easier, and more accurate by providing helpful information directly in a worker’s field of view. Here are some ways AR is used to improve supply chain management:

Benefits of AR for Real-Time Problem Solving

Augmented Reality (AR) helps supply chain teams solve problems quickly by providing instant information right in front of them. Here’s how it makes problem-solving faster and more effective:

Faster Decision-Making

Faster Decision-Making

With AR, teams get real-time information right when they need it, which helps them make quick, smart decisions. For instance, if a shipment is delayed, the team can instantly see possible alternative routes or transportation options to keep things moving smoothly. This fast access to information helps them respond to problems without wasting time.

Reducing Delays and Downtime

Reducing Delays and Downtime

AR helps teams spot issues early, reducing delays and preventing downtime. For example, if there’s a problem with inventory, like low stock or misplaced items, workers can address it immediately using AR guidance. This means the supply chain keeps running smoothly, and disruptions are minimized.

Improving Accuracy

Improving Accuracy

AR guides workers through tasks step-by-step, reducing the chance of mistakes. For example, in picking and packing items, AR shows exactly where to go and what items to select, helping employees work faster and more accurately. This improves order fulfillment and ensures customers get the right products on time.

In short, AR helps supply chain teams work faster, avoid errors, and keep everything on track, which is especially valuable when unexpected problems come up.

Challenges and Limitations of AR in Supply Chains

While Augmented Reality (AR) offers many benefits for supply chains, there are also some challenges that companies may face when trying to use this technology:

Technology Costs and Training

Technology Costs and Training

Setting up AR systems can be expensive. The devices and software needed for AR are often costly, especially for smaller businesses. Additionally, employees need to be trained on how to use AR tools effectively. This training takes time and adds to the overall cost, which can make it harder for smaller companies to afford and implement AR technology.

Data Privacy Concerns

Data Privacy Concerns

Since AR systems track and process real-time data, there are concerns about how this information is stored and protected. Companies need to ensure that private data is secure and handled carefully to avoid any misuse or breaches. This can be a complex process, especially for companies that manage large amounts of sensitive information.

Infrastructure Requirements

Infrastructure Requirements

For AR to work well, companies need a strong internet connection and reliable network infrastructure. AR devices often rely on fast, stable connections to display real-time information accurately. Setting up or upgrading this infrastructure can be costly and may require additional investment, particularly for companies in areas with limited network availability.

Future of AR in Supply Chain

Augmented Reality (AR) is quickly evolving, and it’s likely to play an even bigger role in supply chains in the years to come. Here’s a look at where AR in supply chain management might be headed:

Emerging Trends and Innovations

Emerging Trends and Innovations

AR technology is getting better every day. Newer, lighter AR glasses are making it easier for people to wear and use them comfortably for longer periods. Integration with Artificial Intelligence (AI) is also adding more intelligence to AR tools. For example, AI can help analyze data from AR devices, giving workers more helpful insights and suggestions. Interfaces are also becoming more user-friendly, so people can navigate AR tools without extensive training. These advancements mean that AR will continue to improve and offer even more value in supply chain management.

Predictions for Future Adoption

Predictions for Future Adoption

As AR technology becomes more affordable and easier to use, it will likely spread to more companies. Once AR devices are budget-friendly and require less training, more businesses will see the benefit of adopting them to enhance their supply chain visibility. Eventually, using AR could become a common practice in supply chain operations, helping companies of all sizes improve tracking and reducing errors.

Conclusion

Augmented Reality (AR) is transforming supply chains by providing real-time insights that help teams solve problems faster and work more productively. With AR, employees can easily track items, spot issues early, and reduce mistakes. This technology allows workers to complete tasks more quickly, improving the overall flow of the supply chain.

Although there are still some challenges, like the cost of technology and the need for training, the advantages of AR in supply chain management are clear. As AR technology continues to improve and become more affordable, it will be a valuable tool for companies to keep up with the demands of a modern, fast-moving world. In the future, AR will likely become an essential part of supply chain operations, helping businesses stay competitive and meet customer needs more effectively.

Related Post

-

F

-

A

-

Q

AR is a technology that overlays digital information, like inventory levels or shipment statuses, onto the real world, often through devices like smart glasses or tablets. In supply chains, AR helps employees see important data instantly, making tasks faster and more accurate.

AR provides real-time information about products as they move from suppliers to customers. It allows employees to track items, spot issues early, and make quick, informed decisions. This visibility makes the entire supply chain more reliable and efficient.

AR can reduce errors, speed up tasks, improve order accuracy, and improve employee training. By guiding workers step-by-step, it helps save time and money while keeping operations smooth.

With AR, employees can find items in large warehouses more easily. It guides them to specific products quickly, reducing search time and improving efficiency. This is especially useful in large or complex storage areas.

Yes. AR can show employees the exact location and steps for picking and packing items. This guidance reduces errors, ensures that customers receive correct orders, and speeds up the fulfillment process.

AR highlights any issues, like product defects or incorrect labels, so workers can address them immediately. This helps maintain high-quality standards and ensures only approved items move through the supply chain.

Implementing AR can be costly due to the devices, software, and training required. However, as technology advances, AR is becoming more affordable, and more companies of all sizes will be able to take advantage of its benefits in the future.

As AR technology continues to improve, more companies will likely adopt it for supply chain management. In the future, AR will likely become a standard tool for tracking items, managing inventory, and ensuring high-quality standards, helping companies meet customer expectations in a fast-paced market.

Want to Scale

Your Business? Let’s Meet & Discuss!

CANADA

30 Eglinton Ave W Mississauga, Ontario L5R 3E7

INDIA

3rd floor Purusharth Plaza, Amin Marg, Rajkot, Gujarat. 360002

Get a Quote Now

Let's delve into a thorough understanding of your challenges and explore potential solutions together

What is Augmented Reality (AR)?

What is Augmented Reality (AR)?